Cellulose Di-Acetat

BIO-based Film

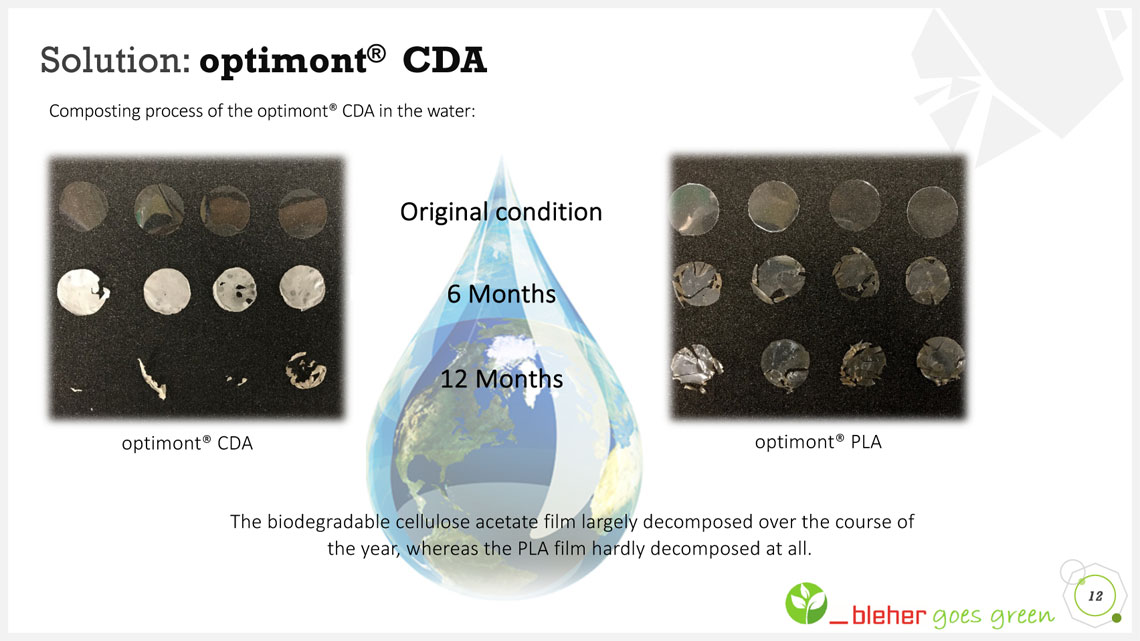

Our optimont® CDA film is a wood fiber cellulose film. This film is made from renewable resources and convinces with its ultra-clear transparency of 0.6% (haze), which is excellent for a "bio-film". Our film is certified for composting according to DIN EN :13432:2000-12 and ASTM D6400 and is suitable for own composting up to a thickness of 75my. The complete composting process takes about 14 weeks. Due to the excellent transmission rate for moisture, good antifog properties and good transparency for UV light (increased UV resistance), the film is suitable as a bio-based alternative for other plastics such as polypropylene, PVC or polyester.

The application range of this film extends from window applications for packaging to lamination and industrial applications.

Product data sheetCONTACT PERSON

Rolls + Sheets

Daniel Blum, Sales Manager

+49 71 52 - 99 77 3-21

daniel.blum@bleher.com

Rolls + Sheets

Eric Geringer, Head of Sales

| Product | Description | Examples of use | Delivery form | Strength (µm) |

|---|---|---|---|---|

| optimont® CDA | Cellulosediacetat (CDA), clear, untreated, natural antifog-effect, superior flatness, food safe, compostable according to DIN CERTCO DIN EN 13432, OK compost HOME up to 115μm, PEFC certificated, OK biodegradable WATER certified Technical data sheet |

Viewing window for packaging, window lamination & patching, print lamination | rolls short rolls mother rolls / master rolls sheets |

14, 24, 30, 50, 75, 95 |

| optimont® CDA | Cellulosediacetat (CDA), clear, untreated, natural antifog-effect, superior flatness, food safe, compostable according to DIN CERTCO DIN EN 13432, OK compost HOME up to 115μm, PEFC certificated, OK biodegradable WATER certified Technical data sheet |

Viewing window for packaging, window lamination & patching, print lamination | rolls short rolls mother rolls / master rolls sheets |

115, 150, 200, 250, 300, 360, 500 |

| optimont® CDA-BIOSEAL | Cellulose diacetate (CDA), crystal clear, 1-sided bio-certified/compostable heat-sealable layer, sealable against cellulose acetate, cellulose trays, PET, PLA as well as many other types of plastic IMPORTANT: The sealing surface is wrapped on the inside of the roll |

Designed for thermal lamination to uncoated board or to be heat sealed to itself | rolls short rolls mother rolls / master rolls sheets |

34,40,67 |

Production of our optimont® CDA films:

Cast cellulose di-acetate film is produced by dissolving di-acetate flakes (wood fibers) in acetone to form a spinning solution (polymer solution). Various additives are combined to improve the processability of the spinning solution and the performance of the resulting film. These include plasticizers, antiblocking agents, release agents, colorants, etc. The spinning solution is filtered, deaerated and poured through a nozzle (the box) onto a continuously moving, highly polished stainless steel belt. Drying takes place both in the belt tunnel and in a drying cabin in a counterflow of hot air. The acetone in the solvent laden air is recovered and reused. The measuring device is controlled by the box gap, the belt speed and the dosing pump rate. The film is wound and then cut according to customer specifications, with residual pieces being recycled.